Soil improvement

Artificial cementation has been used to improve the mechanical properties of local soil e.g. in slopes, under shallow foundations etc. and it can be a key enabler for the treatment of waste materials such as those currently lying in coalfield dumps. Several cementing agents have been adopted in the literature from conventional Portland cement, calcite, fly ash, gypsum, to the more innovative colloidal silica gels and bio-cementation.

The objective of this research is twofold, first to reproduce the main features inherently attributed to naturally cemented soils and to account for changes in their mechanical behaviour and the fabric evolution at various stages of loading; and secondly to evaluate the reclamation potential of depositories of mine waste through recycling; using fly ash, slag and/or microbes as cementing agent.

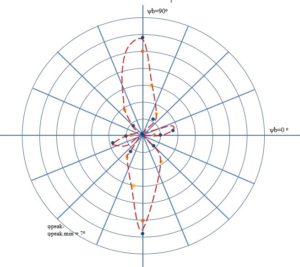

To this end initially the anisotropic behaviour of various mixtures of kaolin and fly ash is investigated in the triaxial and the hollow cylinder apparatuses. The effect of the degree of cementation on observed anisotropy is isolated and accounted for on samples with and without cementation. Static and dynamic loading conditions are investigated.

To this end initially the anisotropic behaviour of various mixtures of kaolin and fly ash is investigated in the triaxial and the hollow cylinder apparatuses. The effect of the degree of cementation on observed anisotropy is isolated and accounted for on samples with and without cementation. Static and dynamic loading conditions are investigated.

Subsequently, coal mining waste materials can be improved and reused through a controlled mix with fly ash, a by-product of burning pulverized coal, or slag and/or microbes, to return to an improved state i.e. with enhanced strength and stiffness characteristics.