Reduced-scale & Numerical modelling

EQUIPMENT

The Soil Mechanics Laboratory facilitates reduced-scale testing, using equipment built in-house (not presently a standard e.g. pullout test, laminar box, transparent sand box, fault rupture box), to assess: (i) the static performance of soil-structure systems and earthfill structures (reinforced, treated, stabilized etc.), and (ii) their dynamic performance using a 2 tons capacity shaking table.

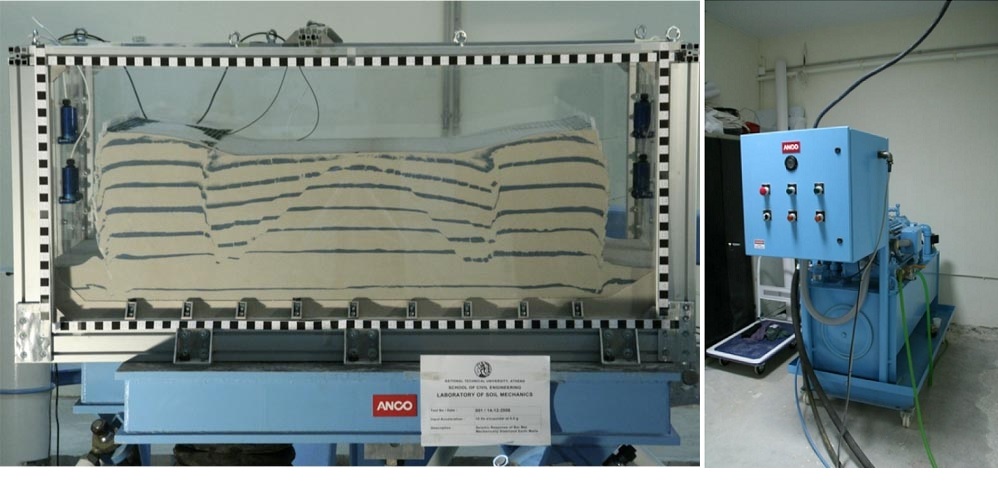

Shaking table

The shaking table apparatus (designed and constructed by ANCO Engineers), is capable of shaking, on a 1.3 m x 1.3 m table, soil-structure specimens of up to 2 tons. With maximum acceleration of up to 1.6 g, for specimen weight of 500 kg, the shaking table can reproduce any ground motion at frequency range between 0.5 Hz to 50 Hz, from synthetic motions to real earthquake records. It has three degrees of freedom (x, y, z) and maximum displacement imposed by the hydraulic actuator of +/- 75 mm. The actuators have a servo-valve controlled by an analog inner-loop control system based on displacement, and a digital outer-loop control system based on acceleration feedback.

Pullout test

The Soil Mechanics lab at NTUA is equipped with a large pullout apparatus having a length L=1.5m, breadth B=1m, and height H=1m. The apparatus is being used to obtain pullout parameters of reinforced earth using various arrangements of reinforcement and backfill materials. Vertical loads are applied using a pushing jack device over the loading plate. A pneumatic cushion is placed between the compacted soil and the loading plate for uniform stress distribution. This is checked with internal stress cells while horizontal and vertical displacements are measured with accuracy of 0.01mm.

Physical modelling of reinforcement pullout tests is accompanied by numerical modelling using ABACUS.

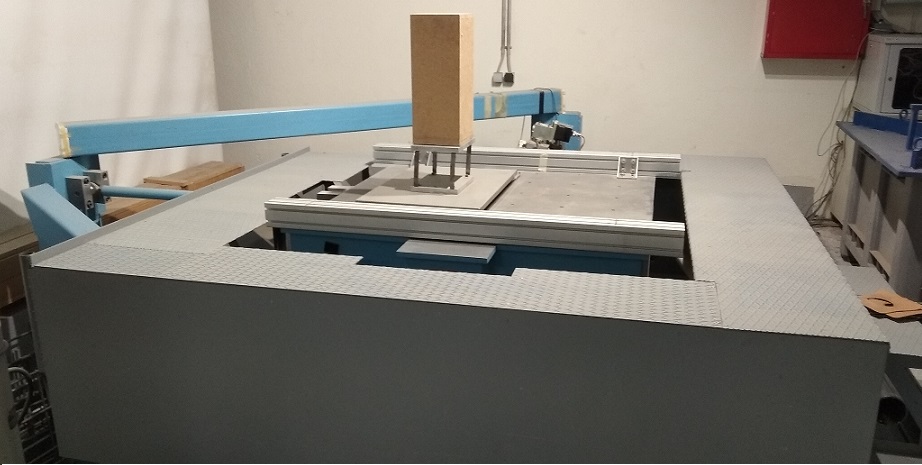

Pushover apparatus

One tonne capacity pushover apparatus with reaction wall, is used for monotonic displacement control (stroke of +/- 500mm, maximum velocity of 50mm/sec) and slow cyclic pushover testing of soil-foundation-systems.

Fault rupture box

The apparatus, which was developed in the laboratory, has a fixed part and a movable part, which can move downwards or upwards to simulate quasi-static Normal or Reverse Fault rupture propagation with a maximum displacement of 200mm in both directions and at a maximum velocity of 5 cm/sec. The angle of Rupture is adjustable from 45 to 90 degrees. The box dimensions are 3 m x 1.2 m x 0.9 m, and can accommodate soil specimens up to 100 cm depth. The long sides of the box are made of Plexiglas to allow observation of soil deformations.

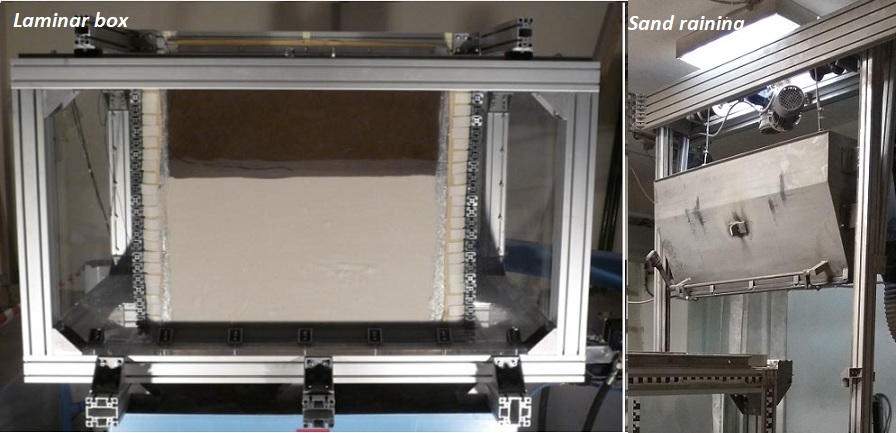

Laminar box

This device, developed in the laboratory, is equipped with a laminar box, allowing the soil to deform freely. The box dimensions are 1.6 x 1 x 1, and can accommodate soil specimens up to 70 cm depth. One of the long sides of the box is completely transparent to allow for the application of visual techniques using image processing, such as Particle Image Velocimetry-PIV. It is also equipped with measurement sensors such as accelerometers, pressure transducers, etc.

Sand box

The sandbox internal dimensions are 1.5 m x 0.8 m x 0.65 m and the long sides are transparent formed by a sheet of glass internally with Plexiglas placed externally for rigidity and durability. The glass minimizes friction and prevents scratching of the Plexiglas.

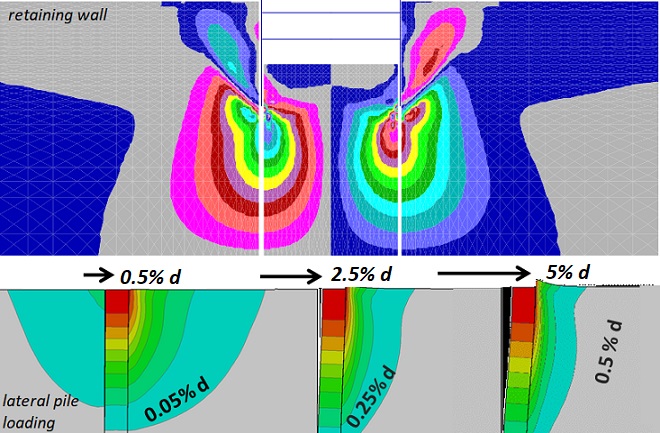

NUMERICAL MODELLING

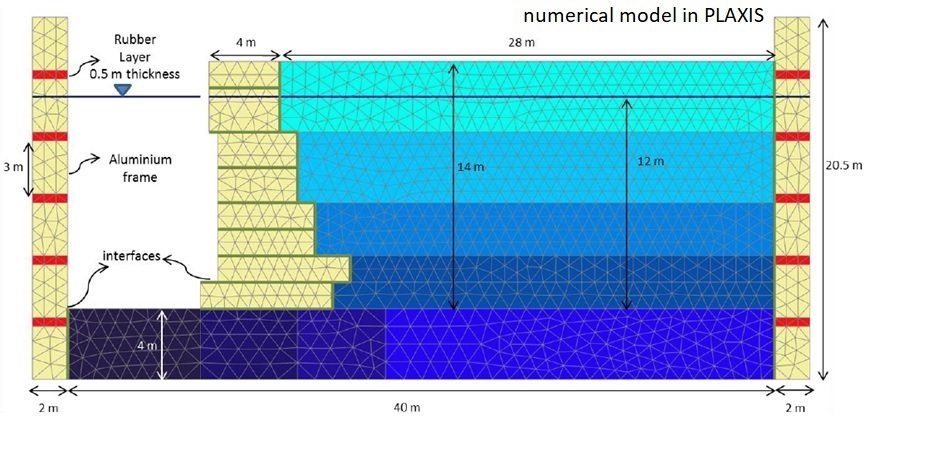

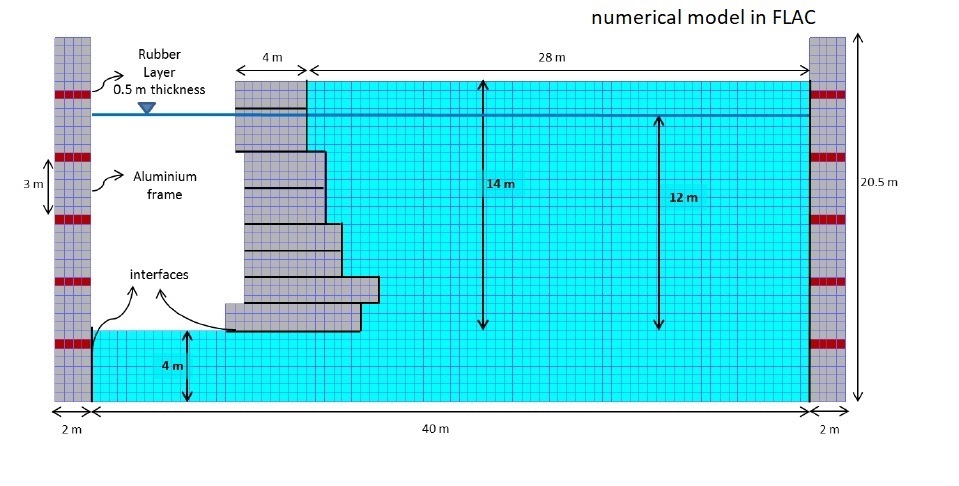

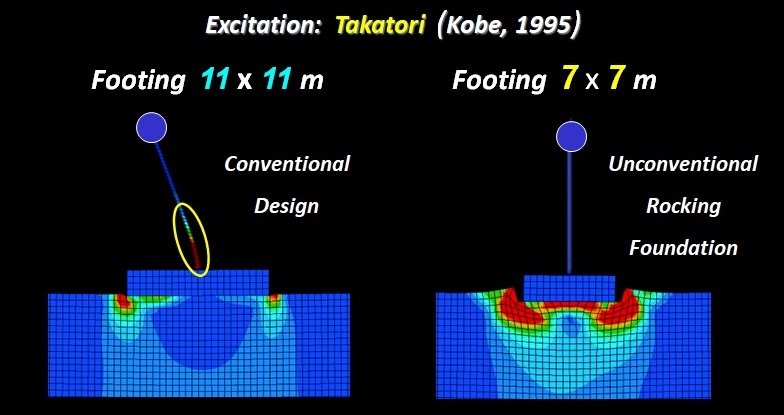

Numerical methods, numerical algorithms, constitutive models and bespoke software are developed; calibrated and validated by advanced element testing. State-of-the-art numerical analysis techniques are employed for the numerical simulation of the static and dynamic performance of soil–foundation–structure systems. 3D numerical analyses (finite element and finite difference analyses) simulate material (soil and superstructure) and geometric nonlinearities (sliding and detachment at the soil-foundation interface), often indicated by reduced-scale testing, to improve our understanding of the key factors affecting the performance of soil-foundation-structure systems.

Applications include site-specific seismic hazard assessment; analysis and design of soil-structure interaction systems, foundations, earth-retaining, earth-fill and underground structures.